Moving Ergonomics Upstream: Proactive Programs Explored Through Alignment with PDCA

Written by: Katie Lonsdale, CCPE, Supervising Ergonomist

Proactive ergonomics is key to preventing injuries from occurring in the workplace and to reducing the costs associated with MSD injuries. However, it is often difficult to identify and justify how and when proactive ergonomics should be integrated into a design process or project. This was accomplished through systematic and methodical program support and tracking of interventions and outcomes across different stages of a client’s New Model/Product Launch cycle.

Exploring how proactive ergonomics can be best achieved is challenging; project planning methodologies can vary across clients and project teams, as does the ability for practitioners to influence how and when ergonomics expertise is integrated into the overall project cycle. By working closely and developing mutual trust with a long-term client, we were able to move our support upstream in the project cycle by visualizing outcomes related to ergonomics support provided across different stages of planning within three projects for this client.

All three projects were new model/product launch related and were completed consecutively. By embracing PDCA methodologies on a cross project basis, we were able to provide metrics and quantitative data that supported shifting proactive ergonomics upstream to maximize input within all design stages.

Findings across three projects:

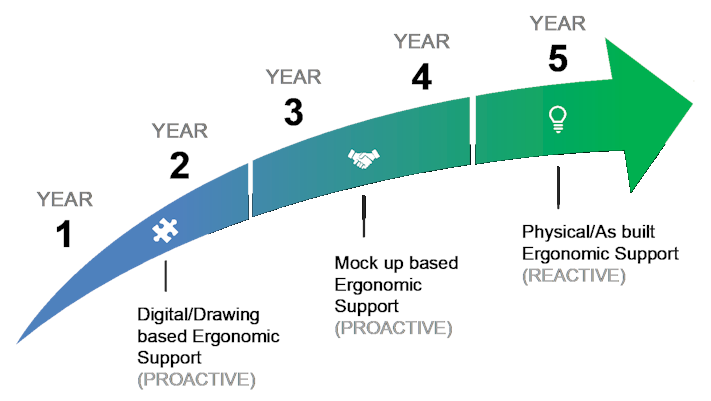

- Project A (reactive ergonomics support): We were invited to join this project 6 months prior to launch. At this end stage of the project, changes were difficult as parts and processes had been established and internal ergonomics goals were difficult to achieve.

REFLECTION: being at the table was a great opportunity to educate, establish relationships, and begin to understand the larger system. - Project B (proactive ergonomics support): Our ergonomics support was integrated into this project early in year three, approximately 2.5 years from launch, in time for the digital design review phase. There were more opportunities to assist with equipment and tool design, however still limited to medium-to-small changes as the part design had already been approved.

REFLECTION: need to create a case and demonstrate the requirement to integrate ergonomics even earlier in the project cycle. - Project C (proactive ergonomics support): Within this project we were integrated into the project team in year 1, prior to design. This integrated an ergonomics perspective throughout planning to influence design and structure changes to maximize opportunities to eliminate risks with increased support from client leadership.

REFLECTION: new challenges exist within this phase that require ongoing work to understand the larger system and metrics.

In short; introducing ergonomics expertise as early in project planning as possible is beneficial to be able to eliminate ergonomic risks and increase the success of project launches. However, even with early intervention, there are additional factors that may influence just how impactful ergonomics can be such as costs associated with recommended changes and the cultural acceptance to changing existing designs and processes. With early intervention, proven results and ongoing education, we are making strides to address gaps and provide improved support with each project.

Utilizing the PDCA methodology has proven valuable to ensuring that lessons learned across all projects can be built upon and used to support advancement and development of future successful risk elimination opportunities.

Feel free to contact us to discuss how we can help you use proactive ergonomics to support and enhance your programs.

Contact Us Back to Articles